Leaking Thermostat and Water Pump Housing in VAG EA888 Gen. 3 Engines

For enthusiasts and everyday drivers alike, the reliability of a vehicle’s engine is crucial, and one of the most common concerns surrounding the EA888 Gen. 3 engines is the recurring problem of coolant leaks. These leaks can often be traced back to the thermostat and water pump housing, a well-known issue in the automotive community for vehicles utilizing this specific engine platform.

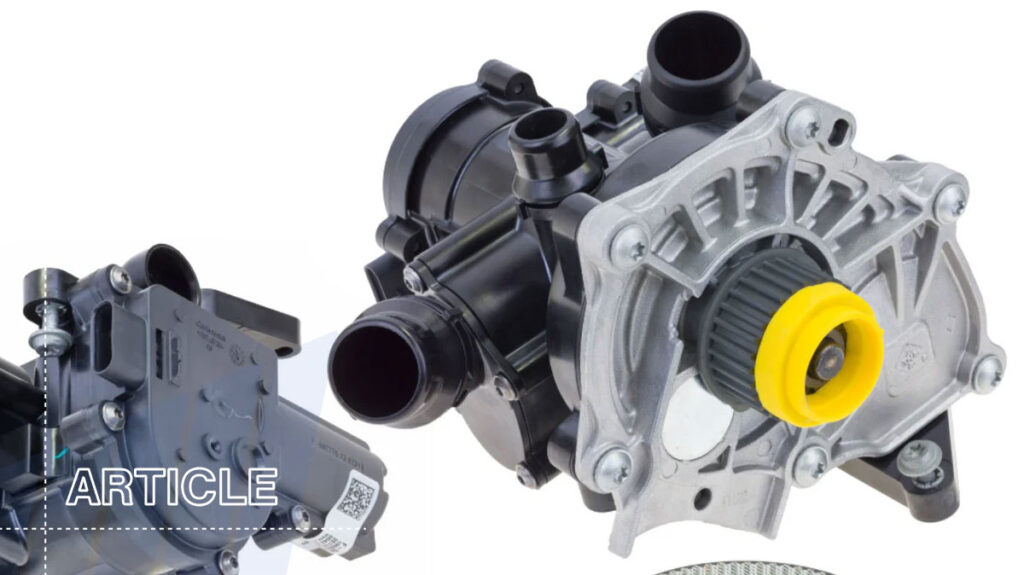

The thermostat and water pump housing on the EA888 Gen. 3 engine plays a critical role in the engine’s cooling system. It regulates coolant flow, ensuring the engine maintains optimal temperature during operation. Unfortunately, many owners of vehicles equipped with this engine have encountered coolant leaks originating from these components. Over time, the materials used in the water pump and thermostat housing can degrade or become vulnerable to cracking, especially under the constant pressure and heat cycling that these engines endure.

- SAVE money over dealer prices.

Why the Coolant Leaks Happen

The main reason behind these leaks stems from the plastic material used in the factory-installed water pump and thermostat housings. The continuous heating and cooling cycle can cause the plastic to warp or crack, creating small but significant gaps where coolant can seep out. This issue is particularly noticeable in vehicles that have higher mileage or those used in climates with extreme temperature variations.

Leaks typically manifest as a loss of coolant, with visible puddles under the car or the driver receiving a warning on the dashboard indicating low coolant levels. If ignored, this can lead to more severe problems like overheating, which may damage the engine’s internals and result in costly repairs.

Why Early Detection is Key

As with many engine-related issues, catching the problem early is crucial. Keeping an eye on your vehicle’s coolant levels and regularly checking for leaks can help you avoid more severe engine damage. If you notice any signs of coolant loss, it’s important to address the issue as soon as possible to avoid potential engine overheating.

Routine inspections and maintenance of your engine’s cooling system can help ensure that your EA888 Gen. 3 engine continues to run smoothly and reliably. By being proactive and replacing the faulty water pump and thermostat housing with an improved kit, you can extend the lifespan of your engine and maintain the performance that makes these engines so well-regarded.

What Can Be Done to Fix It?

The good news is that this problem has a straightforward solution. The affected thermostat and water pump housings can be replaced with new, upgraded units that are designed to be more robust and resilient to heat and pressure. By installing a replacement kit, you can effectively address the issue and restore the cooling system to proper working order.

- SAVE money over dealer prices.

For those looking to fix this issue themselves, we offer a Genuine VAG 1.8/2.0 TSI EA888 Gen. 3 Water Pump and Thermostat Kit, which includes all necessary seals and union parts to ensure a secure and reliable fit. This comprehensive kit has been designed specifically to resolve the coolant leak issue and prevent future problems.

You can find the replacement kit available for purchase here. This kit comes with all the essential components, making it an excellent choice for those looking to replace their faulty thermostat and water pump housing.

In Conclusion

The coolant leak issue on the VAG EA888 Gen. 3 engines due to the thermostat and water pump housing is a common problem, but it’s one that can be fixed. If you’re experiencing coolant leaks or seeing a drop in your coolant levels, the solution is a straightforward replacement of the affected parts. Our Genuine VAG 1.8/2.0 TSI EA888 Gen. 3 Water Pump and Thermostat Kit offers a reliable fix, ensuring your engine remains cool, efficient, and ready for the road.